If you are a person, who is doing business in the electrical and electronical fields. Then it is mandatory to obtain electrical items from the best electrical manufacturers. These people provide raw materials to their clients. Then in the manufacturing industries all the raw materials are assembles and they are made in to an electrical or an electronical device.

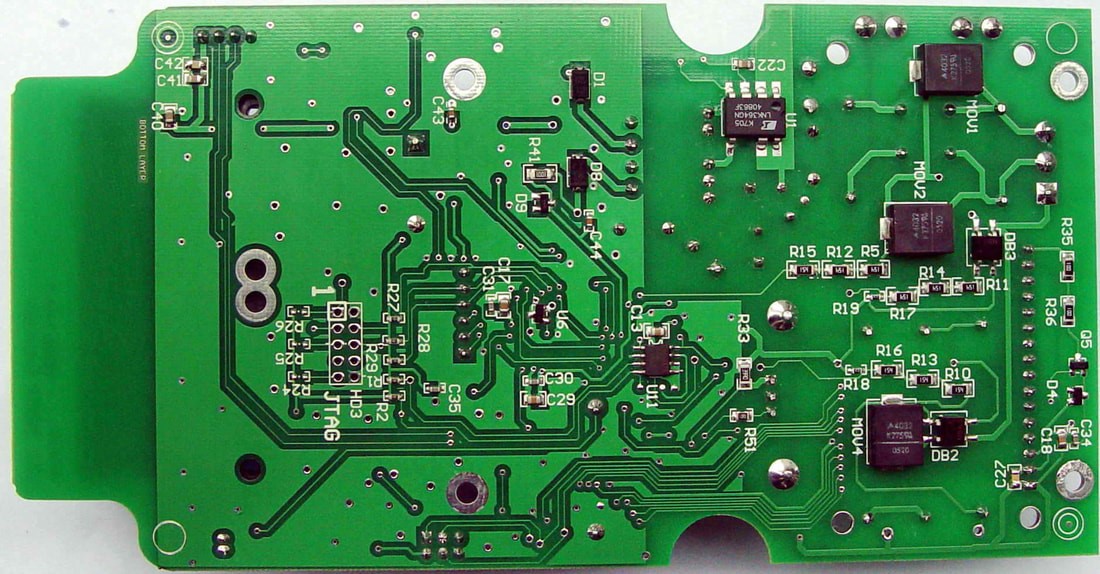

The electrical and electronic devices is made from following certain methods. The components are made by using printed circuit boards. These PCB’s should be brought from the best manufacturing industries. By using certain methods to assemble electronic components on these PCB. This can be done by using many methods. One such method is known as the Surface Mount Device.

What is meant by Surface Mount Device?

Surface Mount Device is a method of creating electronic devices. It is done by placing the small electrical components on the printed Circuit board. In this method, the electronic components are mounted over the printed circuit boards. While choosing the printed circuit boards (PCB), we should consider certain essential features. They include quality of the printed circuit boards and their reliability.

So the main thing to consider while proceeding with surface mounting procedure, is to select the perfect surface mount device.

Selecting the suitable PCB

The printed circuit boards should be of the best quality. It should be reliable and it should bae flexible enough. The printed circuit boards can be classified into two types, they are. Flexible printed circuit board and Rigid circuit boards. The Rigid printed circuit boards are those, which are rigid. They are used in creating the electronical applications.

The flexible printed circuit boards are those, in which the PCB boards are flexible. These flexible printed circuit boards are those which is very flexible and which can be fixed into small spaces. These flexible printed circuit boards can be used for the purpose of making electronic devices.

PCB Manufacturing

The most important component for the Surface Mount Device method is the PCB. These PCB’s should be manufactured and bought from very quality assured and trusted company, like Ray PCB, which is present in China. These PCB manufacturing industries provides the fabrication techniques in the high-quality boards. This industry also manufactures the printed circuit boards according the customer’s needs and requirements.

This industry manufactures printed circuit boards at good quality. The service provided by this company is very good and hence they maintain a very good relationship with their customers.

Assembly of PCB

The PCB should be assembled in the proper way. Most of the companies orders only for the raw materials like printed circuit boards. But Ray PCB is such a company which offers both the raw materials and also the assembly work. Some of the manufacturing industries and the organization also requires the full key process. The full key process is defined as the method, in which the overall process of the manufacturers starting from the PCB manufacturing and up to the deployment of the made electronical components.

Testing process in the PCB

PCB can be tested in two ways. In one method all the units of the printed circuit board are tested. The units present in the printed circuit boards are tested based on their placement and control structures. This is known as the unit testing method and the other testing method is known as the functionality testing method.

In the functionality testing method, all the functionalities of the printed circuit board components are teste. In this method different sub methods also used for the accuracy. Some of the methods are in circuit testing and AOI inspection method.Likewise, many methods are present for testing the functionality of the printed circuit board. So, Guys! the above mentioned are the steps involved in processing the printed circuit boards. In the process of selecting the surface mount device we have to look for the best printed circuit boards available in the market with maximum quality. The manufacturing industry also should assure guarantee and assurance to their products. These companies should be selected based on the previous reviews of the customers. The Ray PCB is one such company which offers quality and trust assured products to the customers. The customers and clients of the Ray PCB is found all the world. So while selecting the surface mount device, the selection should be done for best manufacturing companies like the Ray PCB one.

RELATED ARTICLES

Latest Articles

How Professional Services Firms Manage C…In Technology

How Professional Services Firms Manage C…In Technology LeetCode Login: Step-by-Step Guide to St…In Tipes

LeetCode Login: Step-by-Step Guide to St…In Tipes Why Smart Glasses Are the Next Big Thing…In Fashion, Technology

Why Smart Glasses Are the Next Big Thing…In Fashion, Technology Vicky Jain Net Worth 2026: How He Built …In Biography

Vicky Jain Net Worth 2026: How He Built …In Biography World’s Largest Eagle: Why Experts…In General

World’s Largest Eagle: Why Experts…In General Dame Jean Macnamara: Woman Who Transform…In Biography

Dame Jean Macnamara: Woman Who Transform…In Biography Scaling Quality Control With High-Precis…In Medical

Scaling Quality Control With High-Precis…In Medical The Role of Communication in Protecting …In Tips

The Role of Communication in Protecting …In Tips

stopie.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com.

Clicking on an Amazon link from stopie.com does not increase the cost of any item you purchase.

We will only ever link to Amazon products that we think our visitors may be interested in and appreciate learning more about.