What Are the Most Common Electrical Failures in Agricultural Machinery?

varsha June 18, 2025 0 COMMENTS

Imagine yourself working against time to bring in your crops before the weather turns during harvest season. Your combine harvester sputters to a stop out of nowhere, leaving you stuck in the field with acres of grain still to be gathered. Usually, the cause of these annoying breakdowns is an electrical failure avoidable with correct knowledge and maintenance, not a mechanical one.

Sophisticated modern agricultural equipment depends mostly on sophisticated electrical systems to run anything from engine management to GPS guidance systems. These technical developments have transformed farming efficiency, but they have also brought fresh difficulties with maintenance and troubleshooting. Knowing the most frequent electrical failures will save you time, money, and the trouble of unplanned downtime during important farming seasons.

Table of Contents

Charging System Issues with Batteries

Any electrical system begins with power generation and storage; thus, battery and charging issues are among the most common ones farmers run across. Operating in hostile environments with high temperatures, vibrations, and dust exposure that rapidly reduces battery performance, agricultural equipment must be robust.

Particularly harsh on batteries, cold weather greatly reduces their capacity and makes starting heavy machinery challenging early on in morning operations difficult. Constant vibration from field activity can also loosen battery connections and, over time, damage internal components. Many farmers find too late that their alternator isn’t adequately charging the battery, which causes unplanned middle-of-important-task shutdowns.

Preventing these problems now depends critically on regular battery testing and maintenance plans. While investing in premium batteries meant for agricultural uses pays benefits in dependability, keeping terminals clean and connections tight can greatly extend battery life.

Wiring Harness Degradation

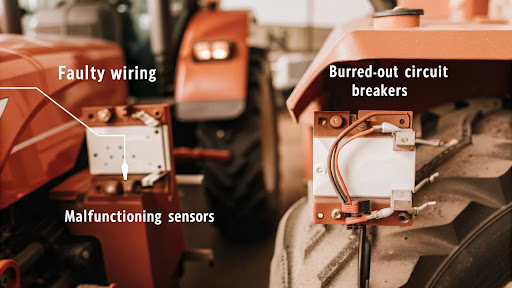

Operating conditions for agricultural machinery are some of the toughest known ones; nowhere is this more clear than in the state of wiring harnesses following many seasons of use. Constant exposure to moisture, chemicals, rodents, and physical stress wears on electrical connections all around the equipment.

A damaged tractor wire harness can produce notoriously difficult-to-identify intermittent electrical problems. Symptoms might be flickering lights, inconsistent sensor readings, or systems that run flawlessly one day and then fail the next. The difficulty is that these harnesses sometimes feature hundreds of wires passing through difficult-to-reach and inspectable areas.

For many farmers, rodent damage presents an especially annoying issue. Naturally drawn to the warmth and cover machinery offers during storage, mice and rats have an unfortunate inclination to chew on wire insulation. Usually invisible until the equipment is required for the next season, this kind of damage causes expensive delays and repairs.

Failures of Sensor and Control Module

To maximize performance and guarantee correct operation, today’s agricultural tools mostly rely on sensors and electronic control modules. These sophisticated parts track ground speed and implement position as well as engine temperature and hydraulic pressure. Should these sensors fail, the whole performance of the system may be compromised.

Common reasons for sensor failures in agricultural uses are dust and moisture intrusion. Even sensors meant for hostile conditions can finally give in to the continuous exposure to dirt, chaff, and changing weather. Though usually more strong, control modules can also fail from voltage spikes, overheating, or just wear over time.

Modern diagnostic systems are complex; thus, finding failed sensors or modules usually calls for specific tools and expertise. Knowing common failure patterns and symptoms, however, will enable farmers to decide when to call professional help instead of trying repairs on their own.

Problems in the Lighting System

Safe operation during early morning, late evening, and nighttime work periods typical of planting and harvesting seasons depends on proper lighting. Unfortunately, the rough operating conditions of agricultural environments especially affect lighting systems.

Among the main enemies of agricultural lighting systems is vibration. Especially prone to filament breakage from continuous bouncing and jarring during field operations are conventional incandescent bulbs. Although conventional incandescent systems can experience connection issues and driver circuit failures, LED lighting has significantly improved reliability.

Another often occurring issue causing early bulb failure and electrical connection corrosion is water intrusion into light housings. Correct sealing and routine component inspections can prevent many of these problems before they become safety concerns.

Strategies for Prevention and Maintenance

Using proactive maintenance instead of waiting for issues to develop will help to reduce electrical failures. Frequent visual inspections of connections, wires, and electrical components help identify possible problems before they cause expensive breakdowns.

Reliability of equipment depends much on a methodical approach to electrical maintenance. This covers creating consistent plans for applications of protective coating, connection cleaning, and battery testing. Maintaining spare fuses, bulbs, and often failing sensors in stock guarantees that little problems don’t become major causes of delay.

Additionally, environmental protection is very important for preventing electrical failures. Simple steps, including correct equipment storage, rodent control, and moisture protection, will greatly increase the lifetime of electrical components. Working with credible photovoltaic wire manufacturers for solar installations guarantees that additional power systems maintain the same dependability criteria as the machinery they support as agricultural operations progressively include renewable energy solutions.

Last Thought

Knowing and stopping common electrical failures in agricultural equipment is not only about avoiding inconvenience; it’s also about safeguarding your investment and guaranteeing seamless operation of your equipment depending on timing. Early recognition of the warning signals of battery problems, wiring degradation, sensor failures, and lighting concerns will help you to proactively handle these issues before they affect your output.

Throughout many successful growing seasons, performing regular maintenance, utilizing proper storage techniques, and understanding the electrical systems of your equipment will prove to be very beneficial. Remember that many common problems can be avoided or resolved with simple knowledge and consistent attention to detail, even while some electrical problems call for professional expertise.

What electrical problems with your agricultural tools have you run across? In the comments below, share your knowledge and maintenance pointers to help other farmers stay free from such mistakes and maintain seamless operations.

RELATED ARTICLES

Latest Articles

Jagermeister 750ml Price in India: Full …In Whisky Prices

Jagermeister 750ml Price in India: Full …In Whisky Prices Building a Scalable Payment Infrastructu…In Technology

Building a Scalable Payment Infrastructu…In Technology Tech-Savvy Ways to Streamline Your Finan…In Business

Tech-Savvy Ways to Streamline Your Finan…In Business Magic Moments Vodka Price in India: Size…In General

Magic Moments Vodka Price in India: Size…In General The Role of Claims Agencies in Holding A…In Tips

The Role of Claims Agencies in Holding A…In Tips How Embracing Cloud‑Native Strategies Tr…In Technology

How Embracing Cloud‑Native Strategies Tr…In Technology Poorvika Mobiles Pun: Best Place for You…In Technology

Poorvika Mobiles Pun: Best Place for You…In Technology Why Choosing the Right NEET Coaching Mak…In Education

Why Choosing the Right NEET Coaching Mak…In Education

stopie.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com.

Clicking on an Amazon link from stopie.com does not increase the cost of any item you purchase.

We will only ever link to Amazon products that we think our visitors may be interested in and appreciate learning more about.