What Makes Industrial Equipment Cables Different from Standard Wiring?

varsha June 18, 2025 0 COMMENTS

Have you ever wondered why the basic cables running through your house look so different from the cables running through large manufacturing equipment? If you have visited industrial buildings, you have most likely observed that the electrical infrastructure appears designed for war rather than for use in homes. These strong cables reveal a wonderful world of engineering, and knowing their special qualities will help you value the challenging requirements of industrial operations.

Table of Contents

The Foundation of Durability

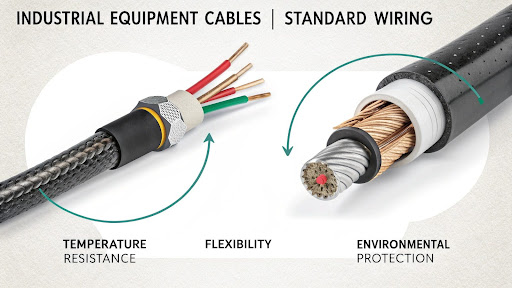

Industrial equipment cables and conventional wiring differ most in their construction philosophy. While your home’s electrical system is meant for a regulated indoor environment with known conditions, industrial cables have to survive in hostile, unforgiving environments where failure isn’t only unpleasant but maybe catastrophic.

Usually made of simple insulating materials like PVC or polyethylene, standard household wiring is excellent when shielded inside walls and conduits. Still, industrial cables are designed with several layers of protection. Industrial cables frequently combine specialized polymer compounds, cross-linked materials, and even metallic shielding to survive high temperatures, chemical exposure, and mechanical stress that would rapidly destroy conventional wiring.

The conductors themselves convey a similar story. Typically used in stationary installations, home wiring depends on solid copper conductors suitable for Many industrial uses call for stranded conductors with particular strand configurations that offer outstanding resistance to vibration fatigue and flexibility. Over their service life, these cables must flex millions of times without breaking.

Environmental Problems Influence Design

Industrial settings offer difficulties that just do not exist in homes. Consider the conditions found in a chemical processing facility, offshore drilling platform, or steel mill. These sites expose cables to extremes from sub-zero freezing to furnace-like heat, corrosive chemicals that can eat through common materials, and physical abuse from heavy machinery and equipment movement.

This is where specialized engineering truly excels.

- Flame-retardant chemicals included in industrial cables not only resist ignition but also self-extinguish to stop fire spread.

- Their oil-resistant coats hold integrity under hydraulic fluid and lubricant exposure.

- Many industrial cables also feature UV-resistant formulations for outdoor uses where regular sun exposure would cause ordinary wiring to become brittle and break.

Still another important difference is water resistance. While household wiring may come across sporadic moisture, industrial cables often run in conditions where they are routinely exposed to washdown operations, steam, or even total submersion. The materials and sealing techniques used in industrial applications greatly surpass those used in household projects.

Needs for Performance and Power Handling

Industrial equipment’s electrical needs exceed those of domestic appliances. Individual industrial machines can need thousands of amps of current, while your house might only draw a maximum of 200 amps through its main service. This great power demand calls for entirely different approaches to thermal management, conductor sizing, and insulating thickness.

Industrial cables also have to manage voltage levels that would be hazardous and against the law in household uses. High-voltage industrial systems running thousands of volts call for specific insulating systems with exact electrical characteristics. These cables’ construction methods and materials are thoroughly tested to guarantee they can safely contain these energy levels across decades of operation.

Another factor that becomes increasingly important in industrial environments but usually not in households is power quality. To run properly, manufacturing processes sometimes call for very pure, consistent power. Shielding systems used in industrial cables help to reduce electromagnetic interference, so ensuring that sensitive control systems and precision equipment run as they should.

Customized Solutions Demand Specialized Applications

The way application-specific the solutions get is one of the most amazing features of industrial cabling. Designed for a single, unique application where standard products just won’t work, a special purpose cable assembly may be engineered. These tailored solutions show the amazing adaptability and creativity that engineers working on particular problems can produce.

Think through the specifications for mobile tools, including robotic manufacturing lines, conveyor systems, and cranes. These use demand cables with electrical integrity that can withstand continuous flexing, twisting, and movement. These flexible cables’ engineering calls for specialized strand configurations, unusual insulation materials, and well-crafted jacket compounds working together to offer millions of flex cycles without failure.

Regarding Power Storage and Distribution

Modern industrial buildings depend more and more on complex power management systems with the integration of renewable energy sources and backup power supplies. Specialized components like systems for battery cable assembly that link industrial equipment to massive energy storage demand result from this trend. These assemblies have to manage the special difficulties of battery systems, which include high current surges, temperature fluctuations, and the need for dependable connections free from degradation over time.

The design issues for these power distribution systems go beyond basic capacity for carrying current. Industrial battery systems often operate in difficult conditions where vibration, temperature cycling, and chemical exposure can rapidly degrade standard connections. The cables and connections used in these systems are made from special materials and technologies that ensure they work reliably, even in tough conditions.

Compliance With Safety Standards

Safety criteria for industrial cable installations must be far stricter than those for home wiring. Organizations such as the National Electrical Code, Underwriters Laboratories, and many international bodies have developed extensive criteria, especially for industrial use. These criteria cover everything from toxic gas emission during fires to flame propagation properties.

For industrial cables, the testing processes are therefore rather more exacting. Industrial cables are tested in detail, which includes checking:

- how they react to flames,

- chemicals,

- physical damage,

- and how they hold up over time. Residential wires only go through simple tests for insulation and how much current they can handle. This thorough testing guarantees, even under worst-case conditions, that cables will perform consistently over their intended use life.

Choosing the Correct Approach for Your Use

Knowing these variations helps one to better understand why industrial cables cost much more than ordinary wiring and why appropriate choice is so important. In industrial environments, cable failure can cause massive financial losses, equipment damage, safety risks, and manufacturing closures. Reliable operation depends on investing in correctly engineered cables meant for particular uses; it’s not only good practice.

Industrial cabling presents an intriguing junction of materials science, electrical engineering, and pragmatic problem-solving. Operating consistently in conditions that would rapidly destroy conventional wiring, these specialized cables enable sophisticated industrial operations that generate everything we use in our daily lives.

RELATED ARTICLES

Latest Articles

Jagermeister 750ml Price in India: Full …In Whisky Prices

Jagermeister 750ml Price in India: Full …In Whisky Prices Building a Scalable Payment Infrastructu…In Technology

Building a Scalable Payment Infrastructu…In Technology Tech-Savvy Ways to Streamline Your Finan…In Business

Tech-Savvy Ways to Streamline Your Finan…In Business Magic Moments Vodka Price in India: Size…In General

Magic Moments Vodka Price in India: Size…In General The Role of Claims Agencies in Holding A…In Tips

The Role of Claims Agencies in Holding A…In Tips How Embracing Cloud‑Native Strategies Tr…In Technology

How Embracing Cloud‑Native Strategies Tr…In Technology Poorvika Mobiles Pun: Best Place for You…In Technology

Poorvika Mobiles Pun: Best Place for You…In Technology Why Choosing the Right NEET Coaching Mak…In Education

Why Choosing the Right NEET Coaching Mak…In Education

stopie.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com.

Clicking on an Amazon link from stopie.com does not increase the cost of any item you purchase.

We will only ever link to Amazon products that we think our visitors may be interested in and appreciate learning more about.